September 2, 2004 - Wing Jig

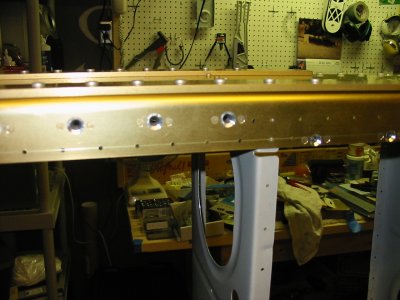

The next step is to build the wing jig. It consists of two 4x4s that support the wing between them. I mounted the 4x4s by bolting them to the overhead joists, and glueing them to the cement floor using "Liquid Nails". This is the right 4x4.

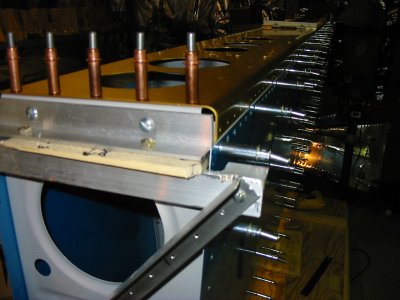

It took me a lot longer than I expected to put this thing together: over a week. But as you might imagine, it's important to build your wing straight and with no twist. I think I made four trips to the hardware store to get nuts, bolts and aluminum angle.

The support where the inboard main spar rests.