October 8, 2008 - Air Scoop

Next item on the agenda was to extend the air scoop opening so that it matches up close to the airbox inlet.

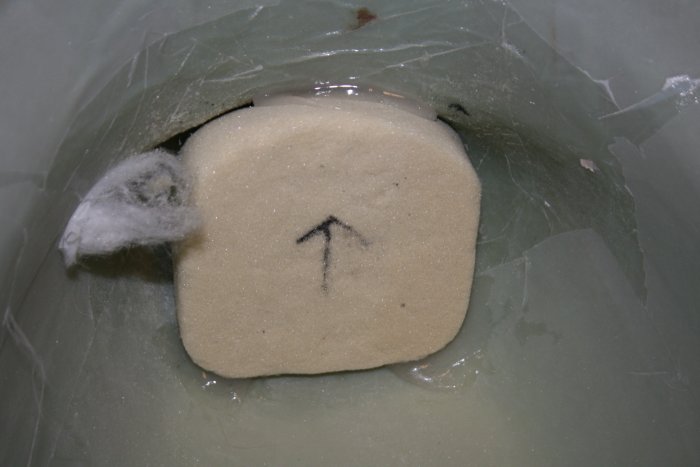

The instructions have you glue the below sanding block in place, hollow it out, and fiberglass the inside of it. Then chip away whats left of the block.

So here I am trying to figure out how to fit the rectangular sanding block in there.

Looks like I'm going to have to trim

the block to get it up against the scoop

inlet.

You can see how the block is wedged

tight against the scoop

inlet.

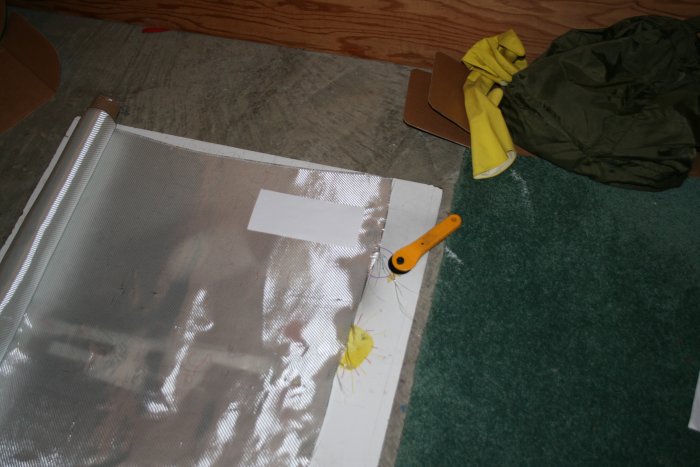

Then I used a course hole file to

widen the opening to the same diameter as the scoop

inlet.

I exposed the glass cloth inside the

block. Of course it won't stay flat without some help. The

instructions suggested blowing up a balloon inside the block to hold the

cloth

tight.

Havn't trimmed this side yet.

I will probably need a follow-up session of fiberglassing to get the "tube" the way I want it.