December 17, 2005 - Fwd Fuse - Aux Longeron

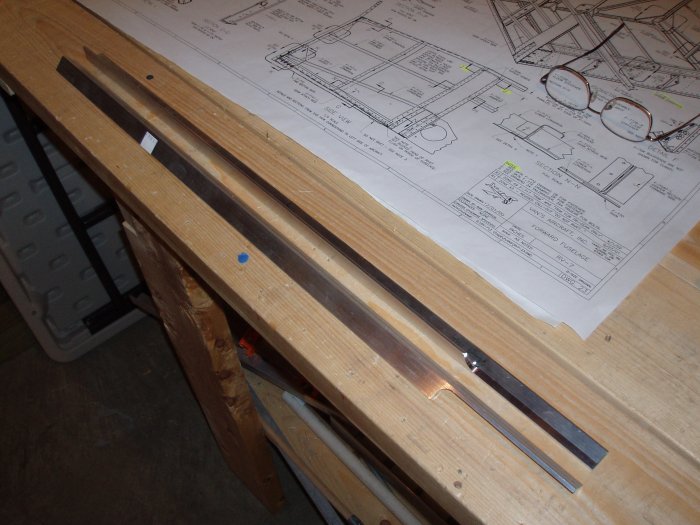

This is a picture of the auxiliary longerons that come in the kit. The forward ends -- in the lower right of the image -- are pre-cut which is nice.

As loyal readers of this page know, I don't have a bandsaw and have been

using a hacksaw to cut my aluminum angle. The way I've been doing

it has consumed more time than it should -- future builders, get a

bandsaw from the get-go.

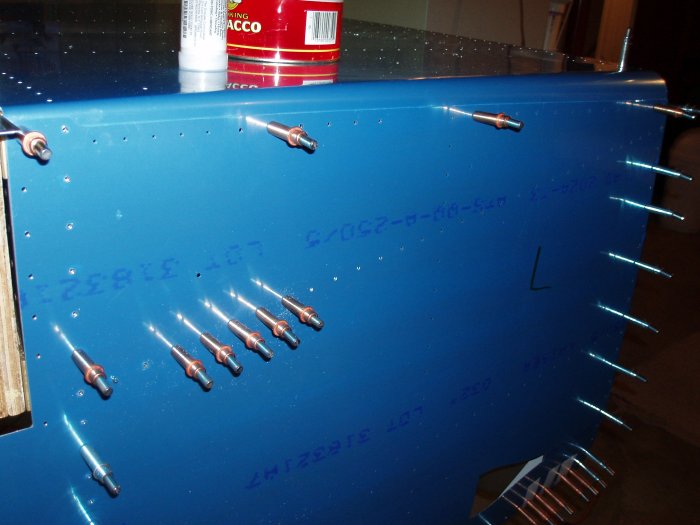

I think I bought the below modeler's saw many years ago at Oshkosh for

use building plastic model airplanes but never really used it. On

an impulse, I decided to try it on the aux longeron. It worked

great! I couldn't believe how fast it cut through the aluminum,

and the line was absolutely straight, and the cut was thin and smooth.

Afterworks, I didn't even need to file it. I just ran some emery

cloth over it. I highly recommend this tool.

One aux longeron is trimmed and one is not.

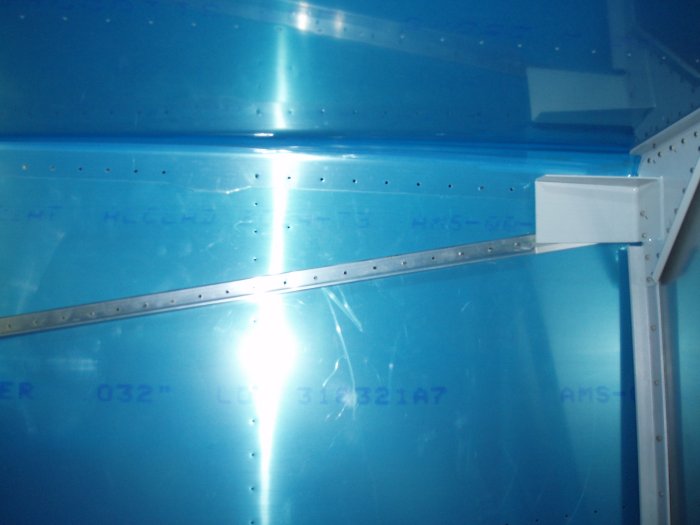

Notice the holes that go through the steel bracket are NOT drilled. The instructions could be a little better in this regard. They tell you to drill the aux longeron; then a couple of paragraphs down, they tell you not to drill the longeron where the steel bracket is. This gets drilled later when you have the gusset in there.