May 14, 2006 - Flap Mechanism

|

|

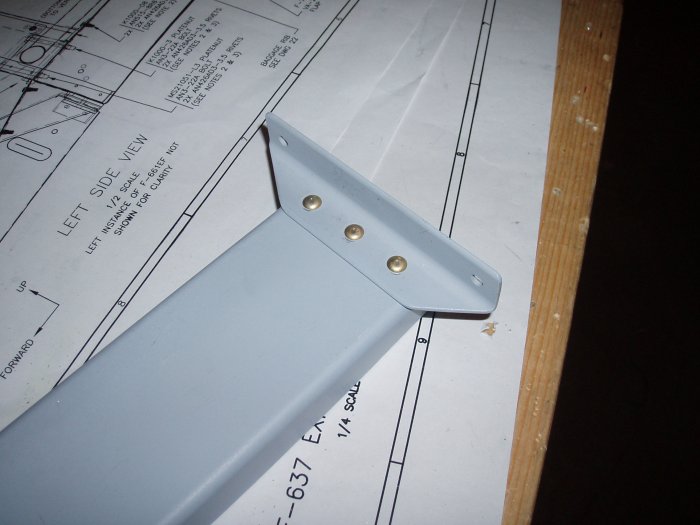

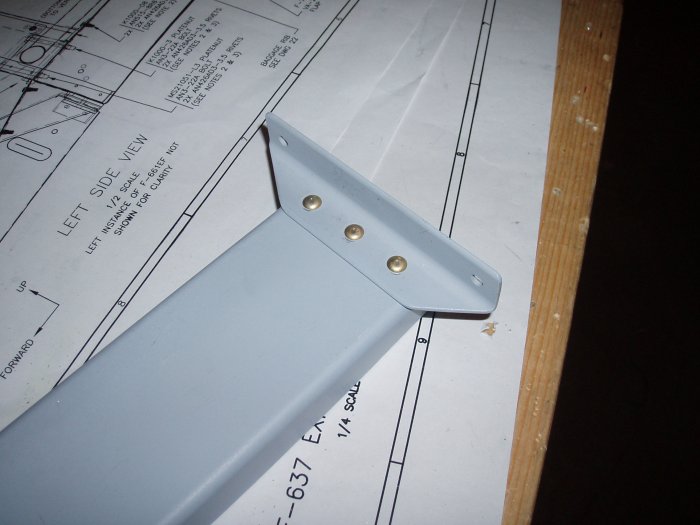

I riveted the lower brackets to the Channel. |

|

|

|

|

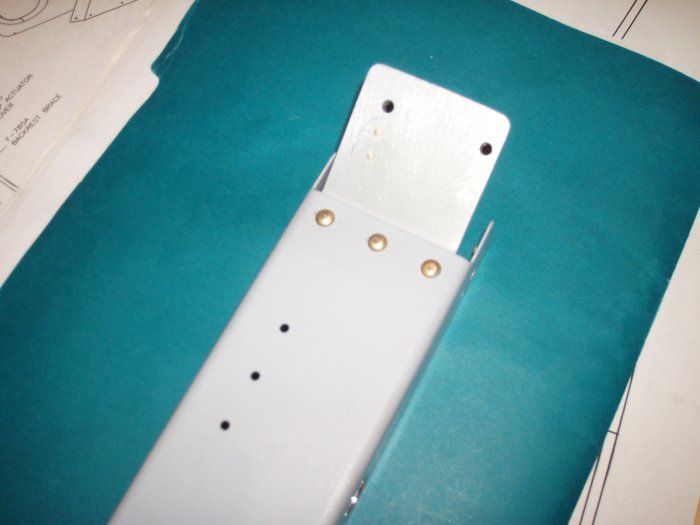

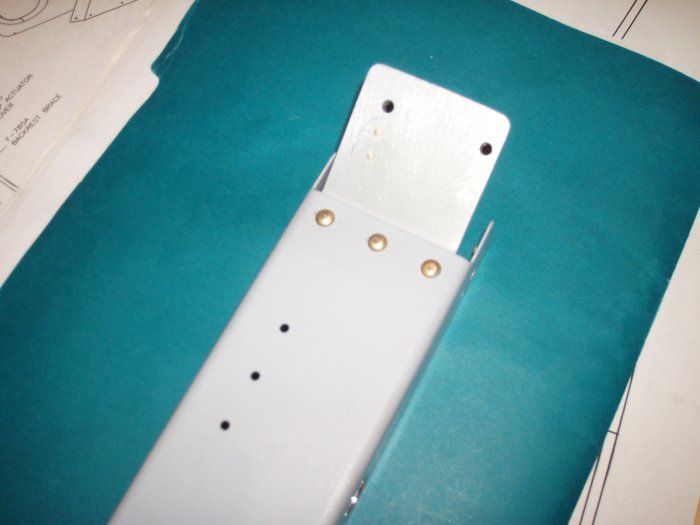

Then I installed nutplates on the Channel sides.

|

|

|

|

|

I drilled out the center hole -- where the Channel bolt goes -- to 5/8

according to the drawings. The two holes on each side of the big

hole got countersunk, since they take flush 1/8" rivets. |

|

|

|

|

Riveting the plate on the inside of the Channel.

|

|

|

|

| Riveting the angle to the bottom of

the backrest brace. |

|

|

|

| Done. |

|

|

|

|

Here I'm bending the F-767 attach plate, that connects the top of the

Channel to the F-705 bulkhead (top-horizontal). This plate gets a 30

degree bend. I put the plate in the vise, laid a piece of 1 by 2

across to distribute the load, and whacked it a couple of times with the

rubber hammer. The bend is shown in a full-scale drawing so I just

compared the plate to it to make sure I had the correct angle. |

|

|

|

|

I clamped the F-766C plate to the top of the Channel, and match-drilled

it, using the channel as a template.

|

|

|

|

|

Now you can finally see what the Channel is. The motor fits inside

the channel and moves the flap actuator which eventually will get attached

to the flaps themselves. I clamped the F-767 to the F-705 bulkhead

and match-drilled it, using the bulkhead as a template. |

|

|

|

|

Then I primed the F-767, installed the nutplates on its backside, and

riveted it to the channel.

|

|

|

|

|

|

|

|

|

|

|