May 13, 2006 - Flap Mechanism

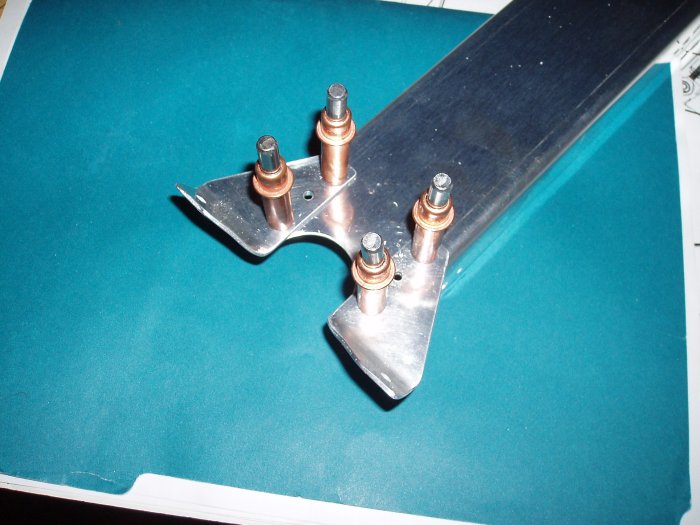

Then I was able to fit the flap actuator and end bearing blocks into the

airplane. I bolted the bearing blocks to the F-705 bulkhead,

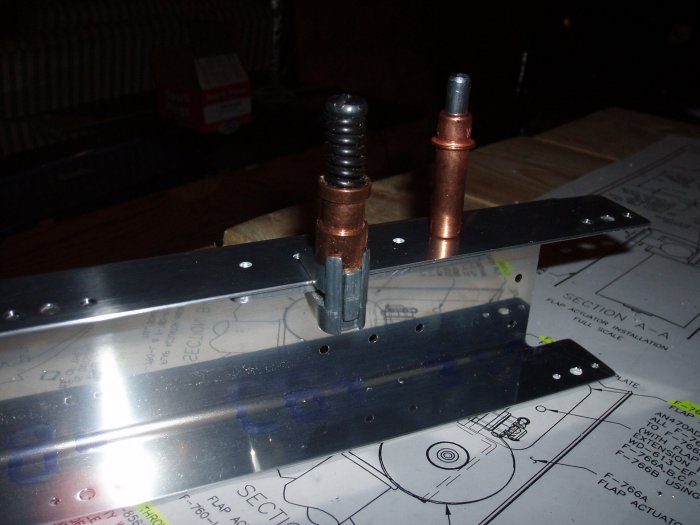

again. I thought I was going to have to undo the bearing blocks

again, because I had not put the center bearing block bottom half in.

Fortunately, I was able to wedge it under the flap actuator without

having to remove everything.

Done. The enter flap actuator will have to come out, though, so I

can install AN-3 nutplates on the baggage floor.

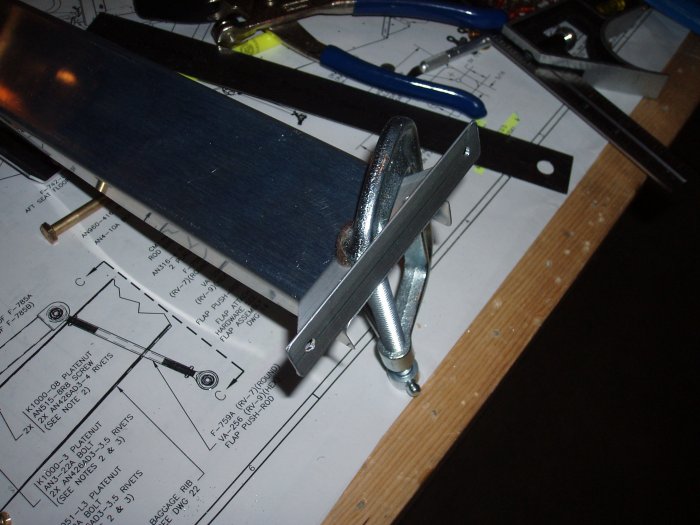

Match-drilling the F-766C plate to the channel, using the channel as a

template.

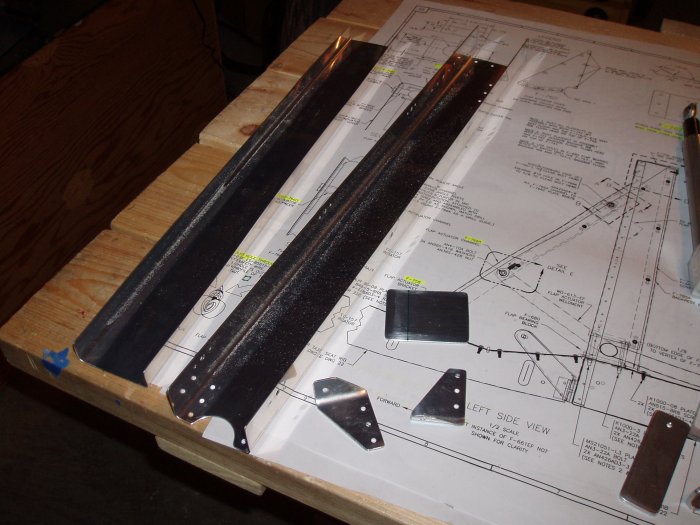

Match-drilling the angle to the Backrest brace. After deburring

everything, I took all the parts out to the garage and sprayed them with

Mar-Hyde so they would be ready for riveting tomorrow.