June 11, 2005 - Fuselage Firewall

This is one of the two angle brackets that I spent way too much time

fashioning out of angle stock. I had worried a little bit about

how I would match-drill it, but like so many aspects of the project,

with a little ingenuity, it was a piece of cake. I clamped

everything together as pictured.

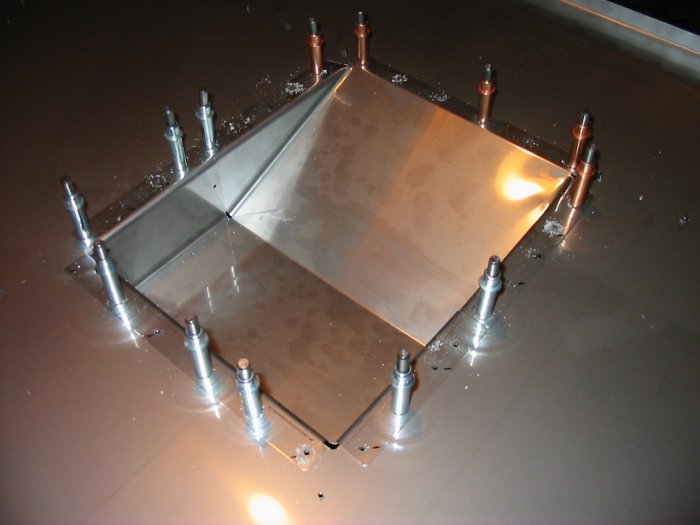

Next I clecoed all the stiffeners to the firewall and match-drilled

them. Because stainless steel will dull your drill bits quickly, I

used lots of Boelube -- the white residue seen in this picture -- and

ran the drill at slow speed, per Van's instructions.

It worked very well, making nice smooth round holes.