February 11, 2006 - Aft Deck

Referring to the drawings, I couldn't believe it when I realized that my original F-711D angle wasn't the correct size! I had used 1" angle instead of 3/4". I fashioned a new F-711D angle -- the correct size, this time -- and match-drilled it to the F-711C bars with the angle-drill. So, it all turned out well. I saved some weight with the correctly sized F-711D angle, and it sat tight up against the longerons. Lesson learned: don't drill the F-711D angle to the F-711C during the building bulkhead phase, but wait until the aft deck stage.

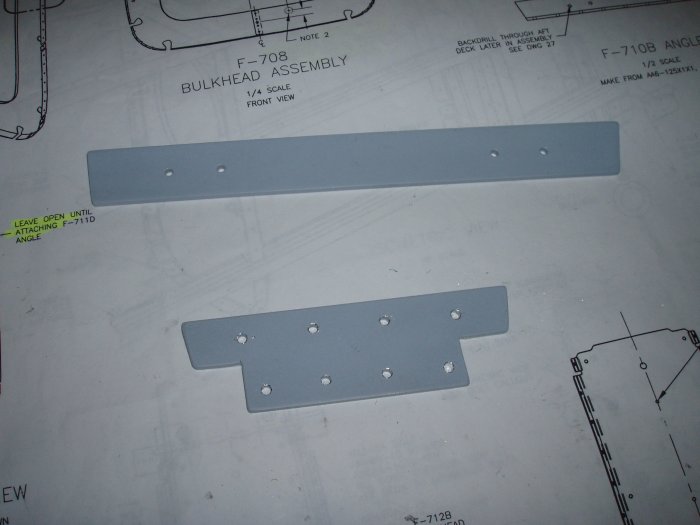

The spacers after drilling and priming.

I primed the aft deck, spacers and angle, then spent a couple of hours

riveting all together. It wasn't what I would call easy riveting

but it came out pretty well. The handled-mirror and flashlight

came in pretty handy for checking the shop heads. I double-checked

with the level for any twist but it still checked 4.0.