December 12, 2004 - Flap

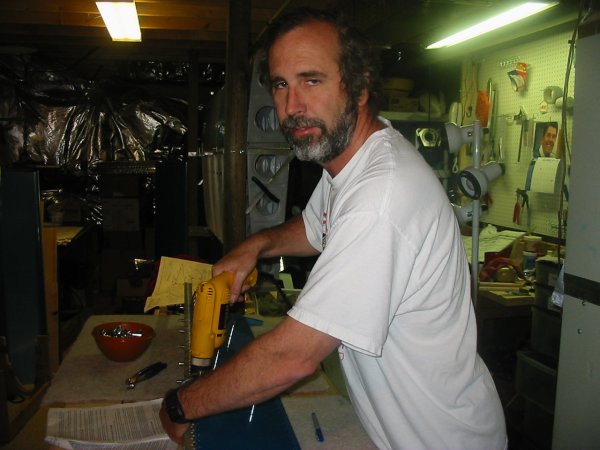

I'm pretty excited about it, as you can see.

All done. The secret to getting the holes in the right place is

drawing a line with the Sharpie where the holes should be. Then,

when the hinge is clecoed to the skin, you make sure the line is visible

through the skin holes.

I used the minimum distance of 3/8" between the hinge edge and hole.

This will give me the maximum about of hinge on the wing side to play

with, so that I can make sure the flap trailing edge is aligned with the

aileron trailing edge.

I had to fashion these shims and flap brackets.