January 22, 2005 - Right Flap

|

|

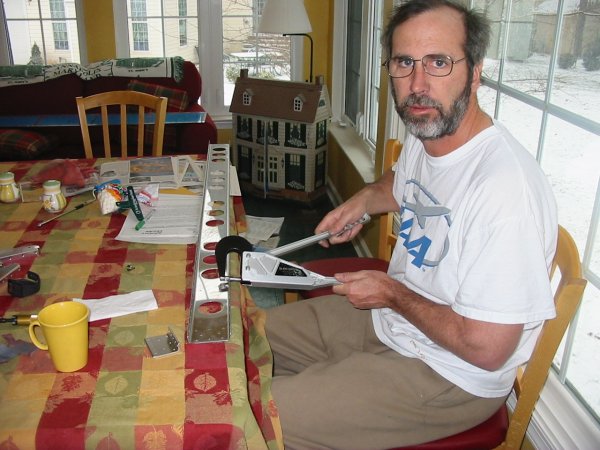

Once all the match-drilling of the flap was done, I took it apart for the

standard prep work: deburring, dimpling, countersinking and priming.

I'm dimpling the spar here. Notice the snow outside and the EAA

T-shirt. .

|

|

|

|

|

Another rare dimpling action shot.

|

|

|

|

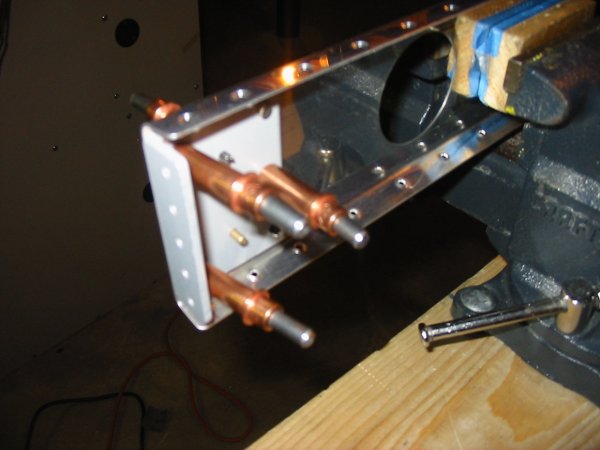

Because of the Hinge, the bottom's a little different. You

dimple the skin, countersink the spar and do nothing except deburr the

Hinge. When countersinking the spar, I had the Hinge clecoed

underneath to act as a guide for the countersink bit.

|

|

|

|

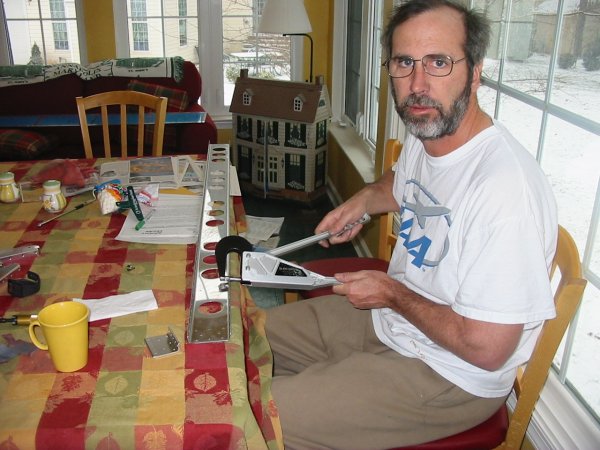

| The next step was to rivet the

reinforcer to the spar. First I had to prime the reinforcers.

This was a problem since it was less than 20 degrees outside. I waited

until the afternoon when it was as warm as it was going to get, sprayed one

side of the reinforcers with the Mar-Hyde, then brought them inside as soon

as they were dry enough to touch. After they had warmed back up, I

took them outside again, and sprayed the other side. I was pleasantly

surprised when the priming seemed to have come out fine -- no adverse

effects from the cold.

In the picture, I'm in the process of riveting the reinforcer to the

spar. |

|

|

|

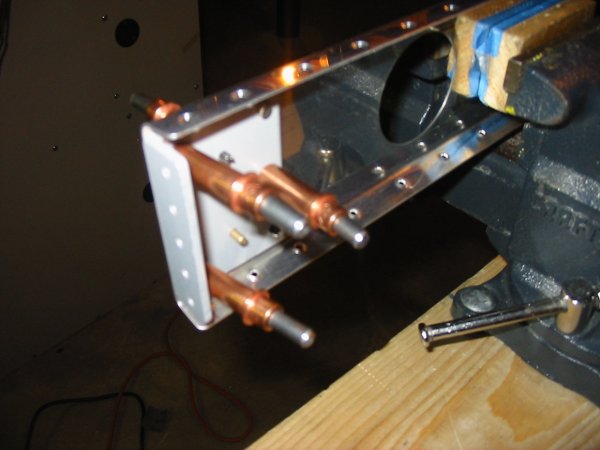

| You can't really see here, but I

have riveted the rib ends to the "virtual" rear spar. I was able to do

it using the hand-squeezer. |

|

|

|

|

|

|

|

|

|

|