November 24, 2006 - Canopy Frame

The next step was to get all the canopy frame components -- the forward section, the side weldments, and the aft channels -- aligned and in their proper position. This is a lot easier said than done. I have read that the canopy is more art than science and I'm not understanding what they mean. The instructions can't say "do this, and then do that" and you come out with this perfectly aligned canopy frame and canopy. The instructions give you some general guidance but it's up to you to get it done. There is a lot of fit it, make adjustments, fit it, make adjustments, and so on.

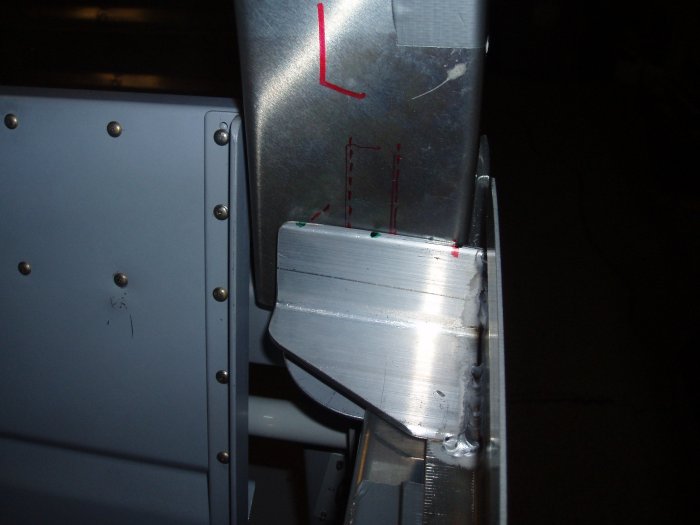

The instructions said to drill the back end of the side weldments according to the drawings. I've been doing this project long enough to know when to pause and say "Whoa, pardner! Let's look at this a bit before we start drilling anything." The back end of the side weldment eventually gets riveted and bolted to the aft channel. This canopy latch lug gets bolted to the back side of the aft channel and goes through that square hole you see in the picture. So the latch lug has to be positioned just right on the aft channel. The middle holes in the back end of the side weldment have to be right spot.

I spent the next three hours or so making adjustments to the side weldment. It got old after awhile. I tried a bunch of things but the most successful was putting the side weldment in the vise and twisting it's forward end with a vise grip.