March 21, 2013 - Upper Wing Spar

Ladders |

|

With the spar flanges done, the next step was to build the spar

ladders. Each spar ladder consists of two spar flanges with

the swallowtail (SWT) blocks and flange spacers between

them.

Here I have laid out two spar ladders with the SWT blocks between

them. Both spar ladders are for the upper wing box

spar. |

|

|

|

|

I had made the SWT blocks previously

but I still had to make the flange spacers. They are made from 5/8"

x 2" stock. So that they would fit tight against the spar flanges,

it was important to make them perfectly rectangular. The table

saw is best for making precise cuts so I used that. |

|

|

|

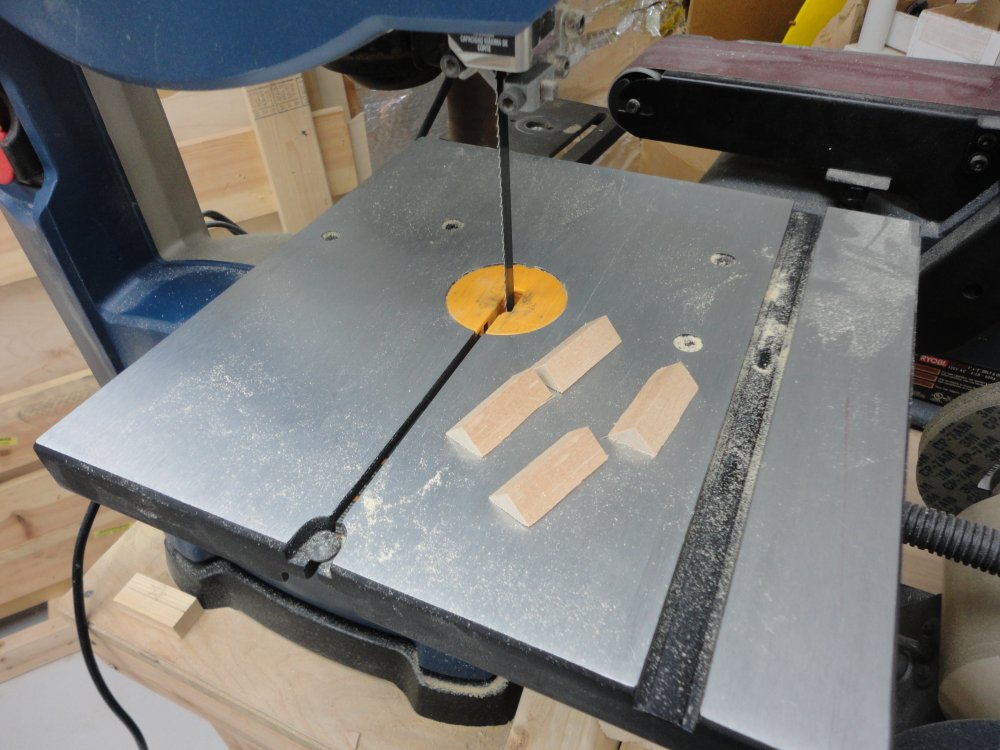

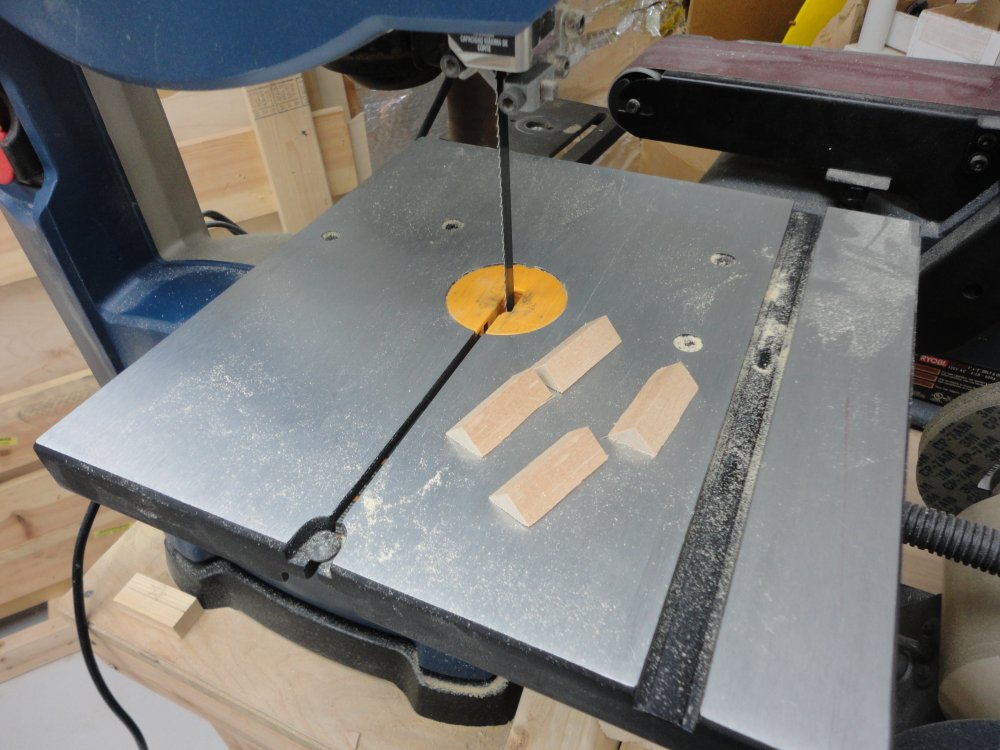

| Because the spar

flanges are tapered, the height of the flange spacers is

variable. In the below picture, I have cut all the flange

spacers but have not cut all of them to height yet. |

|

|

|

|

OK, all of the flange spacers are cut

to height. I also drilled 1/4" holes in them per the plans. I

think the holes are so air can circulate through the box spar. |

|

|

|

| Gluing the first

spar ladder. It took me over an hour to apply the T-88 epoxy to all

the surfaces. It's hard to see what is going on because of all the

clamps and hold-down bars. Plus the ladder is wrapped in wax paper

so it doesn't get glued to the spar table. |

|

|

|

| From another

angle. Lots of clamps were required. Fortunately 8" bar

clamps can be had at Harbor Freight for $4 each. |

|

|

|

| And the first spar

ladder is glued! |

|

|

|

|

From another angle so you can see how

long it is. It is for the upper wing and is 21 1/2 feet long. |

|

|

|

| My lazy assistant. |

|

|

|

|

A trial clamping of the second spar

ladder, in preparation for gluing. |

|

|

|

| Close up of the

flange spacers. |

|

|

|

| The second spar

ladder has been glued. I took this picture to give you an idea how

the spar ladders go together to make the box spar. The ribs slip

over the box spar as shown. There will be spar spacers in between

the two ladders. These have yet to be made. Each ladder

gets covered with thin plywood. The entire box spar gets covered

with plywood as well. So a lot of work remains to be done. |

|

|

|

| From another

angle. |

|

|

|

| The flange spacers

get triangular gussets on each side. These were easy to make using

the band saw. |

|

|

|

| A flange spacer

with gussets. Not glued yet, however. |

|

|

|

| I cut gussets for

all the flange spacers. Ready for gluing. |

|

|

|

| |

|

|

|

|

|

|

|