May 24, 2008 - Air Seal Templates

Lynnette came up with this innovative

prop-guard idea. And donated her pink slippers to the

Cause.

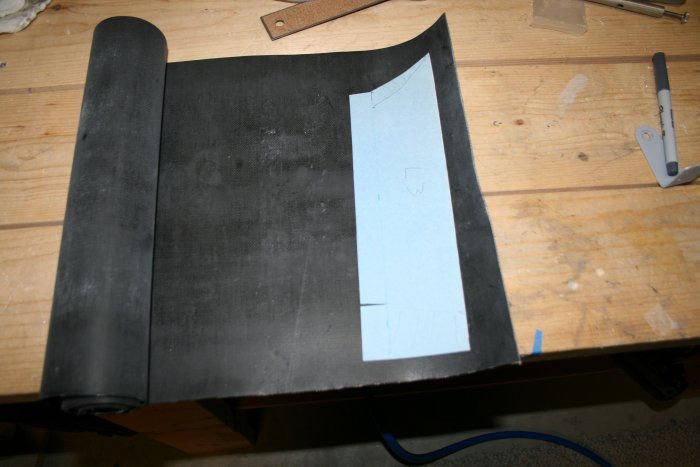

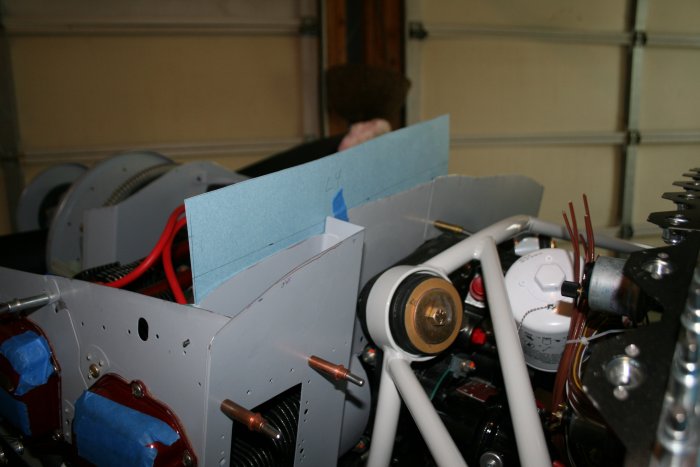

Time to start making the Air Seal

rubber strips. First step is to make templates from poster

board. The instructions say make the strips 3" wide. I figured

I needed 3/4" overlap between the strip and the baffle. That

leaves 2 1/4" of the strip to contact the top cowl

with.

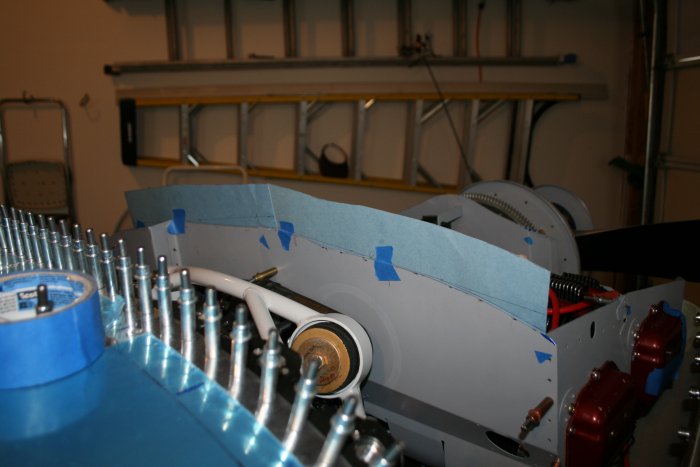

And front done. Not really sure

about what I'm doing at this point. The instructions/drawings are

kind of sketchy and I couldn't find a good builders web site. on this

particular

area.

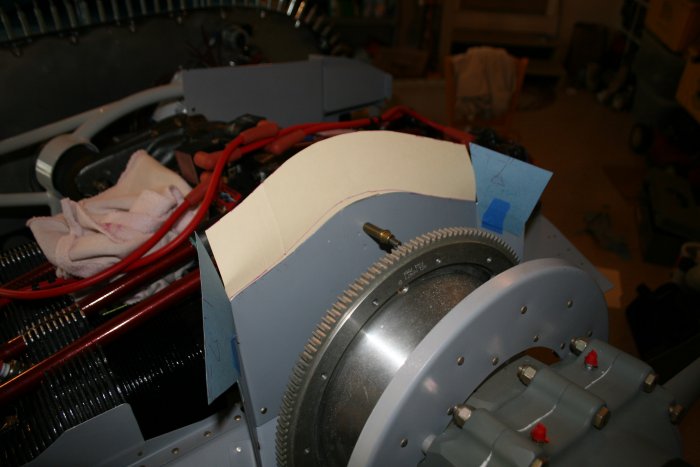

I spent some time pondering the lower

area of the baffles. I hadn't noticed it before, but the right rear

(#3 cylinder) baffle was coming up against the oil return line where the

yellow arrow is pointing. My plan is to remove the flange there, and

bend a new flange higher

up.

Connecting these curved things front

and back is going to be a whole lotta fun.

Not.