January 24, 2009 - Miscellaneous

Weather was almost pleasant

today. Low 40s and

sunny. Got out to the airport

around 11AM. Back to the

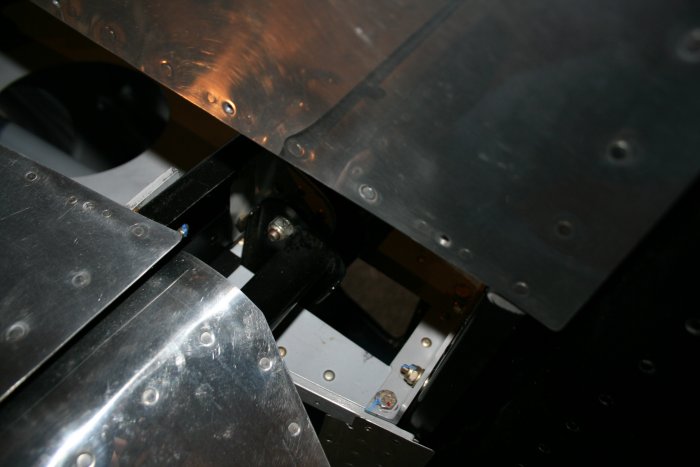

Elevator nut. I tried the new

75 degree wrench and the standard 7/16” wrench grinded down even

more.

So I got the nut tight.

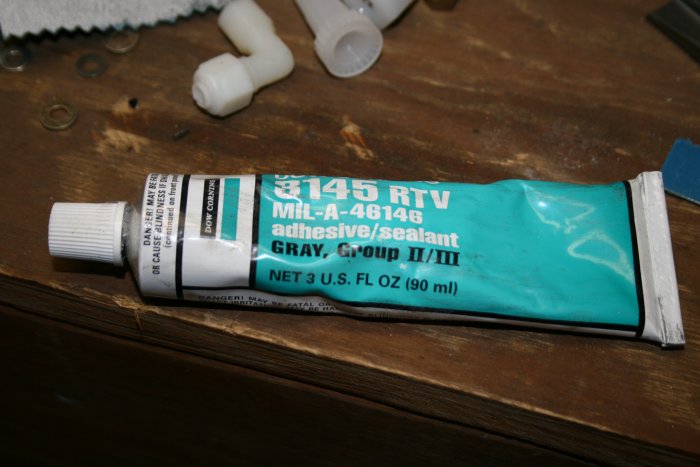

I used this mil-spec RTV to glue the NACA vents to the inside of the fuselage.

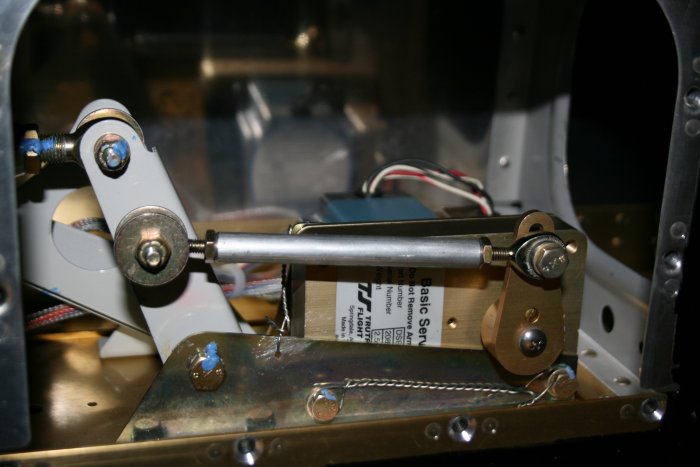

I finished up the

autopilot. Safety-wired the

three bolt heads on the servo.

Screwed down the wiring D-connector. Secured the wire bundle with

tie-wraps. Tightened the jam

nuts on the servo-push-rod.

Used loc-tight on the jam nuts and torque seal on everything. Keep in mind I did all of this laying on

my back underneath the wing! Tested: worked

4.0.