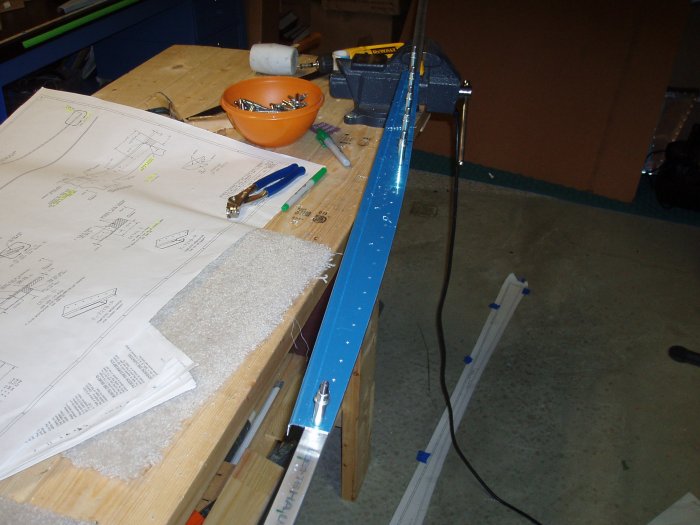

December 4, 2005 - Longerons

First I measured the beginning and ending of the curved area.

I followed the instructions exactly. I secure the angle into the

vise, bend the angle with my hand to put a "pre-load stress" on it, then

whack it with the rubber hammer. Repeat every inch in the curved

area -- roughly 39 inches from the forward end, to 69 inches from the

forward end. Unfortunately, bending the angle horizontally caused

it to bend vertically as well. The instructions say to rotate the

angle 90degrees in the vise and bend it back by hand.

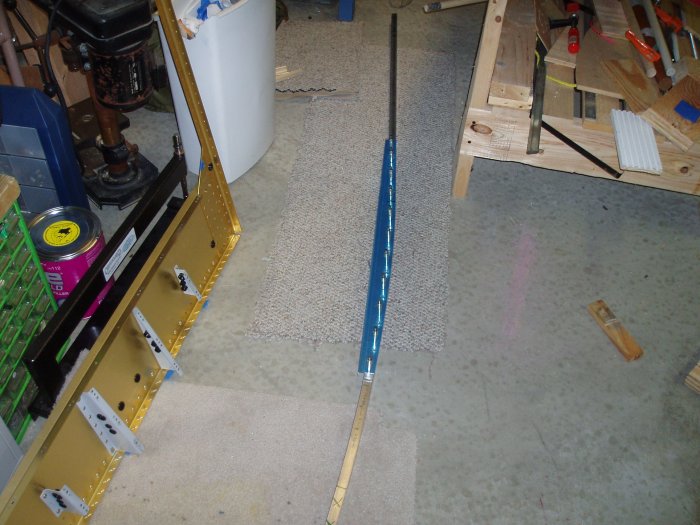

I did all of the above, many, many times. I finally got the thing

banged into shape so that it matched the paper template provided.

The aft ends require trimming. I marked out the area that gets

removed with the Sharpie, then drilled a 1/8" hole as shown. Next

I used the dremel tool to cut along the green lines.