July 30, 2005 - Fuselage F-705 Bulkhead

|

|

We are all familiar with the building steps: drilling, deburring,

de-edging, de-vinyling, dimpling. I have decided to add a new one:

de-labeling. All the parts and stock have a little adhesive label on

them. They almost never come off cleanly. "De-Labeling" is the

act of scraping the labels off, applying some "Goo-Gone" and cleaning off

the adhesive. |

|

|

|

|

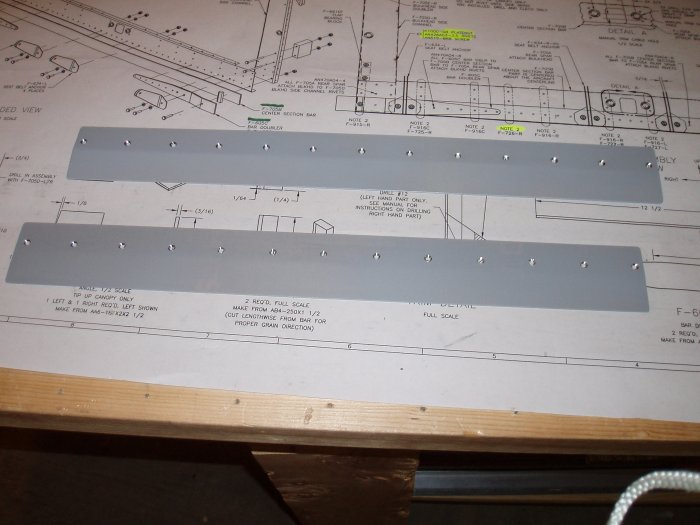

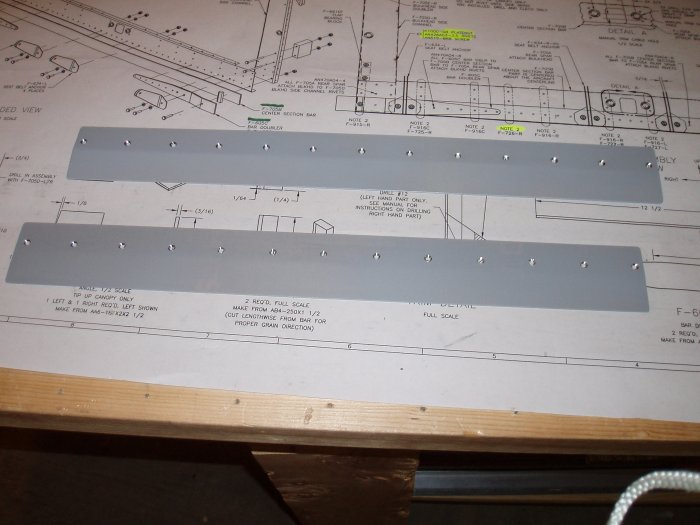

These are all the top-assembly components -- minus the top bulkhead

itself. All are cut, de-edged, drilled, deburred and de-labeled.

|

|

|

|

|

The F-705 bulkhead clecoed together for the first time. |

|

|

|

|

Match-drilling the side assembly to the top assembly. The thick

angle is underneath the clecos.

|

|

|

|

| All the F-705 bulkhead components,

cleaned, and ready for priming with Mar-Hyde. I briefly considered not

priming the alcad-covered parts but quickly decided to prime them, since

this bulkhead -- right behind the seats -- will be visible, will probably be

painted, and should be primed before riveting. |

|

|

|

| I scotch-brited the alcad-covered

parts so the primer would adhere better. |

|

|

|

|

Looking good. |

|

|

|

|

After priming, I realized I needed to counter-sink the top of the

plates.

|

|

|

|

|

Next step: rivet this mess together! |

|

|

|

|

|

|

|