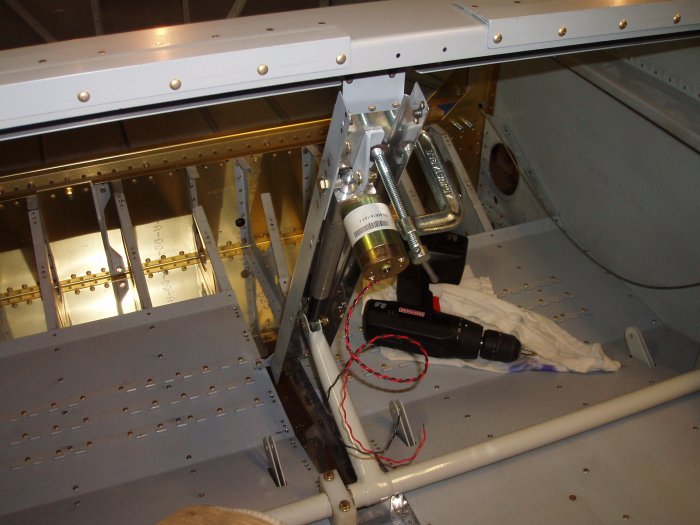

May 21, 2006 - Flap Actuator Mechanism

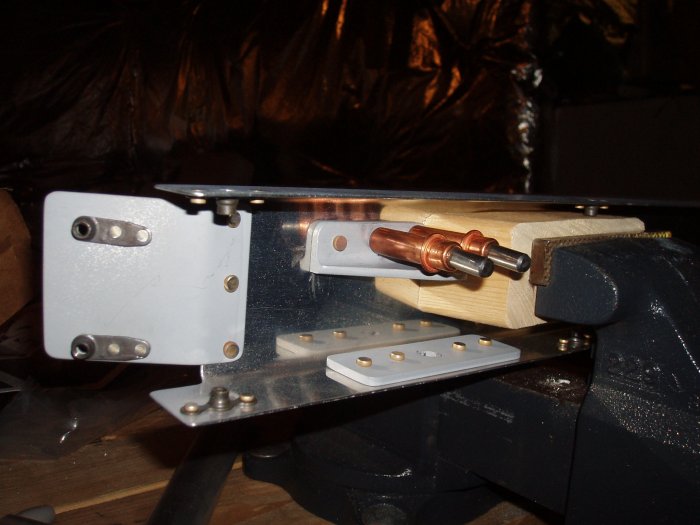

I match-drilled the top and bottom holes, using the channel as a

template.

A better look at how I riveted the channel.

Then I screwed the bottom of the backrest to the floor, and match-drilled the top, using the F-705 bulkhead as a template.

Then I screwed the forward and bottom edges of the the side panels down,

and match-drilled them to the backrest with the #19 bit -- since they

would take #8 screws, using the side panel as a template.

Everything I've been doing the past month or so gets screwed down with

#8 screws into nutplates. I am soooo glad I bought the good

Snap-on screwdriver. It is absolutely amazing how well it grips

the phillips head. And the wooden handle is nice and smooth;

no chafing of the hand. I use a power screwdriver when I can too.

The left wide panel from the forward quarter. I had to "notch" the

side panel where the bolt head protrudes. I made the intitial

notch with the Unibit, then expanded it with the Dremel tool. No

big deal.

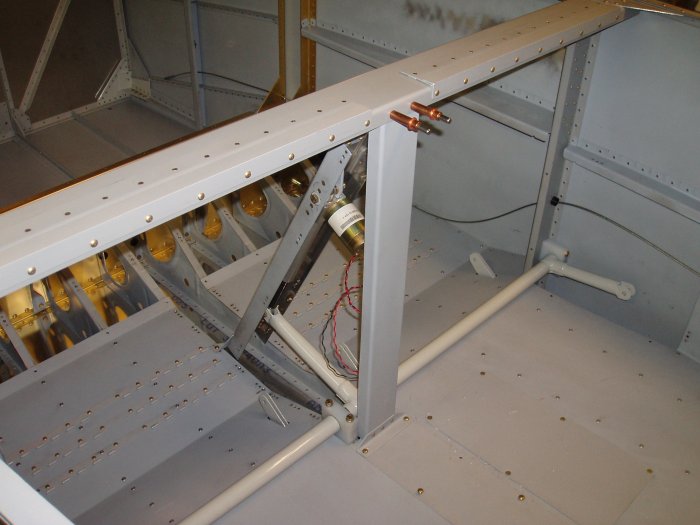

So all I have left to do on the flap actuator mechanism is install

nutplates on the backrest and I'm done.

The next step in the instructions is to fit the wings, but I probably am

not going to do that until after I get back from my Oregon Trail flight

in the Citabria. Until then, I'll work on the Kitfox and perhaps

start on the canopy supports.