October 31, 2006 - Miscellaneous

Then I screwed the panel to the ribs. Why? Because I could.

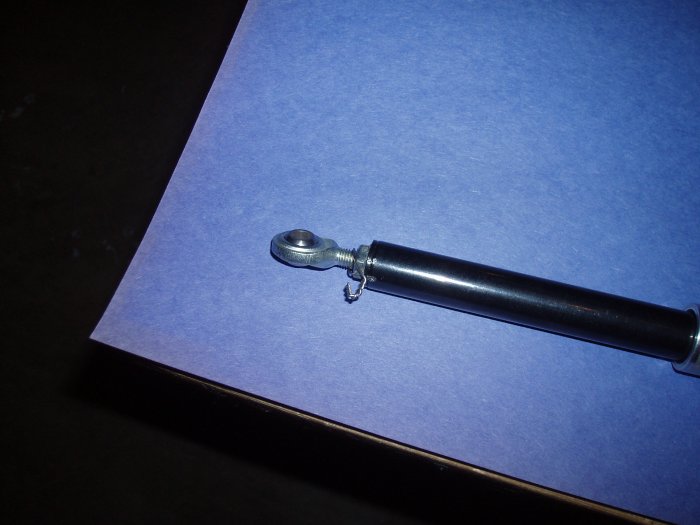

I bought a #3 bit at the local hardware store and drilled each end of

the side latch aluminum tube pushrod with it. Then I tapped each

end. That was harder than I expected -- it was difficult to secure

the tube so I could tap it -- but I got it done. I temporarily put

the latch mechanism together.

But someone had written up a technique in the Vans Air Force forums. With a #37 bit, you start drilling a hole in the side like you normally do. After you get the hole started, you start angling the bit. I tried it and it worked great! So now I one less thing to worry about.