February 1, 2009 - Brakes

The primary focus today was to get everything ready for an engine start next Saturday.

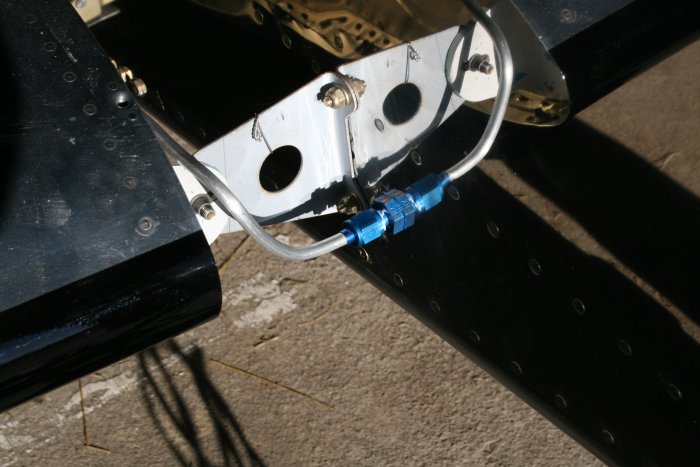

First I made sure all the brake fittings were tight and torqued. I safety-wired the two bolt heads on each brake.

I took off my coat and only had a wool shirt on – and I was hot! It was 60+ degrees outside and sunny – a fantastic day.

Then I tightened up the fuel fittings. While I was underneath the fuse, I put in seven screws on each side that connect the fuse bottom skin to the wing bottom. I put fuel lube on the wing tank fuel vents and tightened them into the wing. The fuel system is ready for the moment of truth – add gas, and … will they leak?

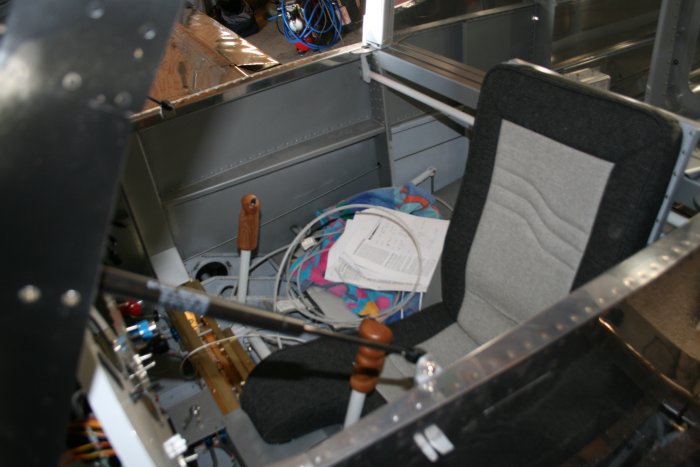

I went to put the pilot-side forward floor in and discovered that the crotch-strap will not fit through the floor. So I had to open up the rectangular hole with the Dremel and file.

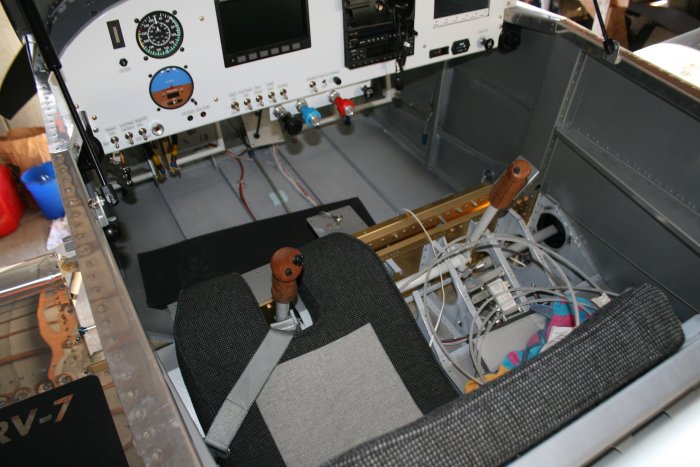

I got the floor on, put in the seat back, and cushions and sat in the airplane. The seat felt great. I started plugging in the Dynon thresholds for the EFIS and EIS. Right away I ran into trouble on the EFIS because I didn’t know what all the Vletters meant. Vans spelled them out and Dynon abbreviated. Will have to research. I had better luck with the EIS, getting most of them.

I wanted to enter setup data into the Dynon, so I put the seat floors and back on the left side, and then the cushions. Then I sat in the pilots seat and entered the engine thresholds into the Dynon: oil temperature, oil pressure, CHT, etc. I wanted to enter the flying thresholds but right away I ran into a problem. The Dynon just says enter day for Vso, Vs1, Vfe, Vno, Vne. But the Van's instructions say "stall speed in landing configuration", "max flap extended speed", etc.

I'm not very good at remembering this kind of thing. The only one I know by heart is Vne -- Velocity Never Exceed Or Your Wings Come Off". Later that night I looked up the V speeds in Wikipedia, and then I was able to correlate the Vans numbers.

On the way out to Essex this morning, I stopped at Martin State Airport and bought 15 gallons of AvGas.

All systems are go for next week's engine start.