February 4, 2007 - Aft Canopy

I needed to trim some more off the center trailing edge so it wouldn't bump into the bulkhead flange on the fuse.

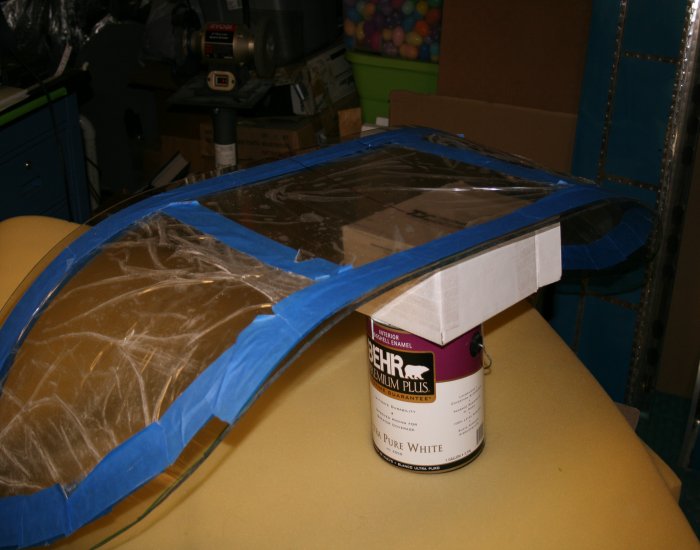

Now I'm able to slide the aft canopy under the aft top skin.

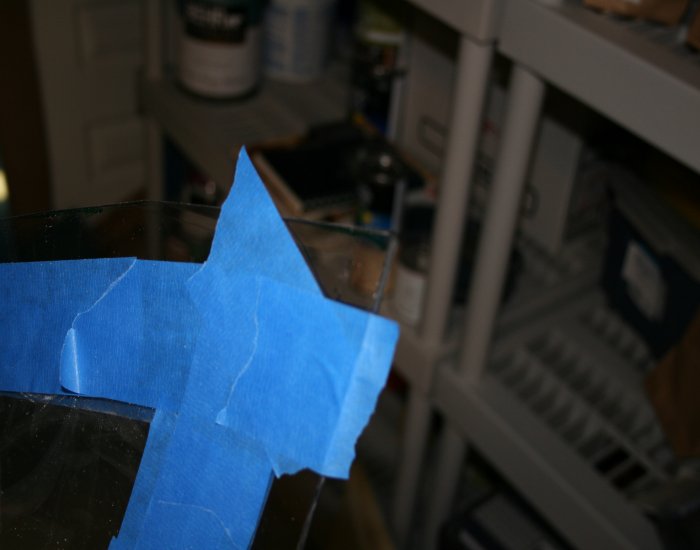

Next I needed to mark where the aft canopy holes would be on the aft top

skin. I spaced the holes 2 1/2" apart per the drawings and about

5/32" inch from the edge. I drilled #53 pilot holes (close to

1/16") like Dan Checkoway did.

There is plenty of canopy "overhang" on the inside.