August 23, 2008 - Canopy Fairing

The wings and empennage are ready for painting. But there are still things I need to do on the fuselage before it is ready for painting. The remaining task that is probably the most involved is fairing the canopy leading edge. So I decided to start with it.

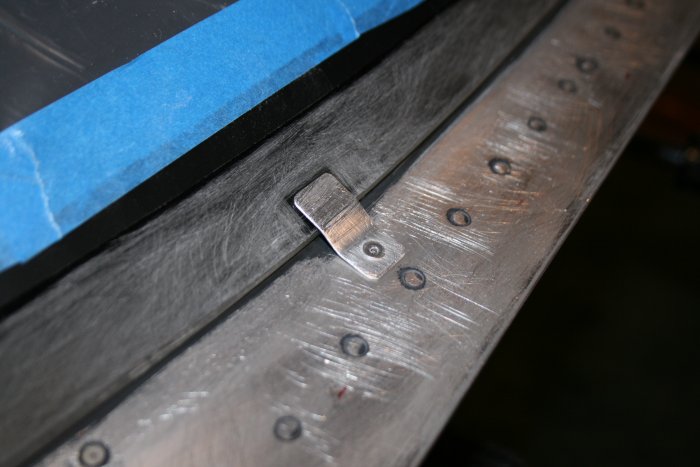

First thing to do was make little hold-down tabs out of aluminum strip. Pretty easy to make.

I protected the front part of the canopy with plastic. The canopy is covered up to the electrical tape barrier. In this picture you can see all four clips.

Then I mixed up a batch of epoxy and micro-balloons -- very thick mixture -- and applied to the area where the canopy meets the skin. I let it dry overnight.

There were some posts in Vans Air Force forums about the oil filler door "bulging" outward in flight. I gathered the impression it's a good idea to strengthen the door so it won't bulge. Initially I tried using some .032 angle but that didn't work for me because of the door curvature. Fluting wouldn't work because the angle needed to curve in the wrong direction.

So I fashioned these two pieces of foam. I sanded one side so they fit the door curvature nicely. I'll glass them over to give them strength.

The canopy fairing instructions call for the application of glass strips. While I was waiting for the Epoxy-Micro to dry, I started cutting out the glass strips, starting at 1/2" and increasing each strip by 1/4". The last strip was 2 1/4" wide.

I have the circular cutting knife -- can also be used to cut pizza in an emergency. Before I had cut the fiberglass cloth on a plywood sheet worked OK but not great. Just by chance, this time I used a hard surface wall-board as the cutting surface. What a difference! Using the circular knife alongside a wooden yardstick cut the fiberglass perfectly.