May 6, 2007 - Flap Hookup

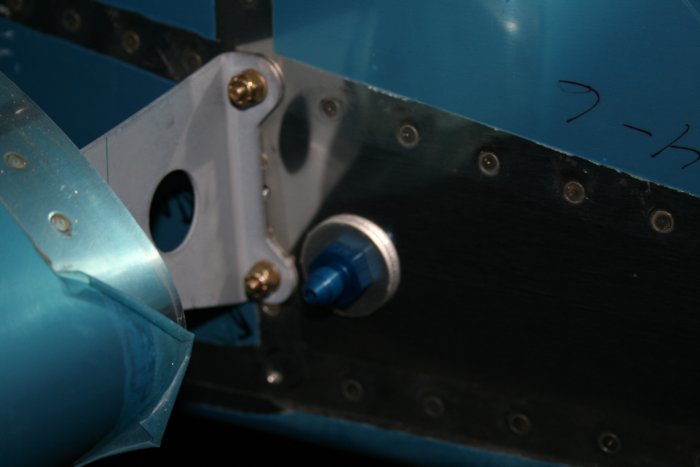

Then I enlarged the hole with the Dremel tool.

The vertical part of the hole was a little higher than I'd like but I

needed it that nigh so that the rod end bearing jam nut wouldn't hit the

skin.