November 29, 2004 - Aileron

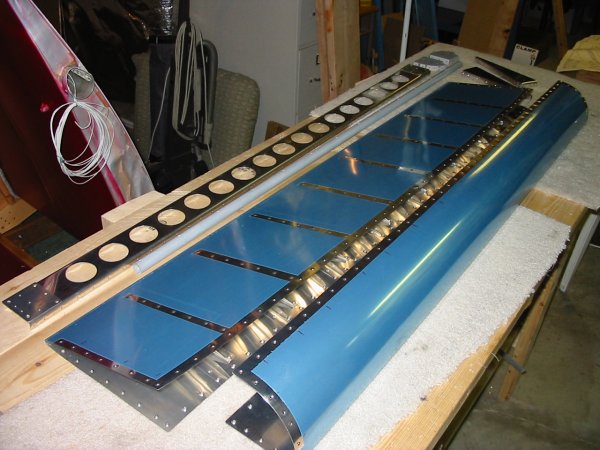

The aileron with the leading edge skin clecoed on. Notice the pipe

in the leading edge. That's a steel pipe which weighs a ton and

acts as a counterbalance for the aileron. Ready for match

drilling.