July 11, 2009 - Gear Fairings & Wheel Pants

All

done.

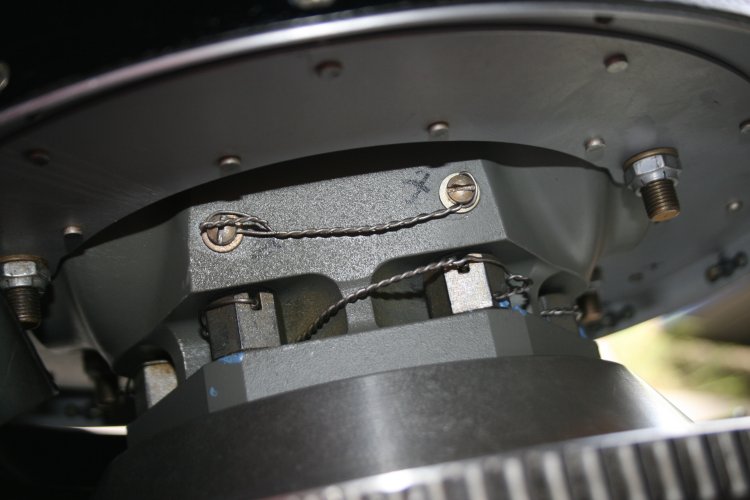

I match-drilled the wheel pants

together.

I only jacked the hoist until the main gear just came off the floor.

The instructions also called for lifting the tail into the flight position. I discovered that with the front-end lifted, I couldn't lift the tail end. Lesson learned -- lift the tail first, then the front end.

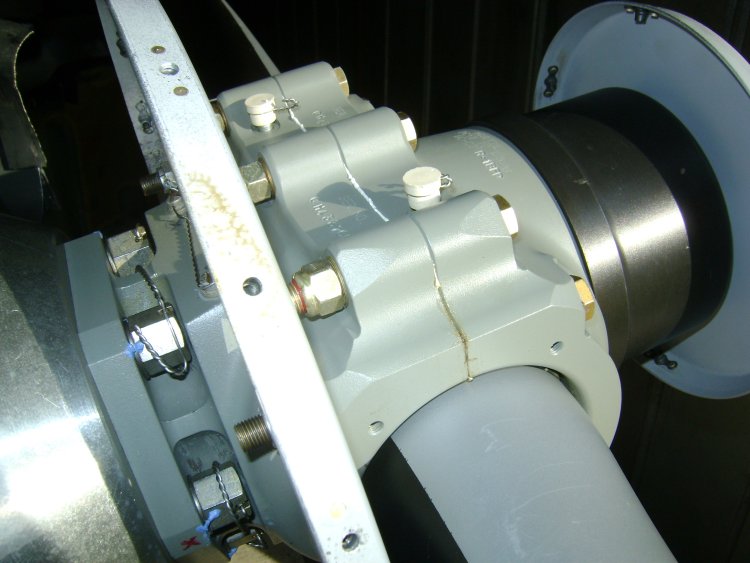

I was surprised with how much

trimming I had to do to the wheel pants to get them to fit.

Here is a picture of the notice cut out in the aft wheel pant to get it to

fit around the gear strut.

I match-drilled the wheel pant to the

outboard bracket.