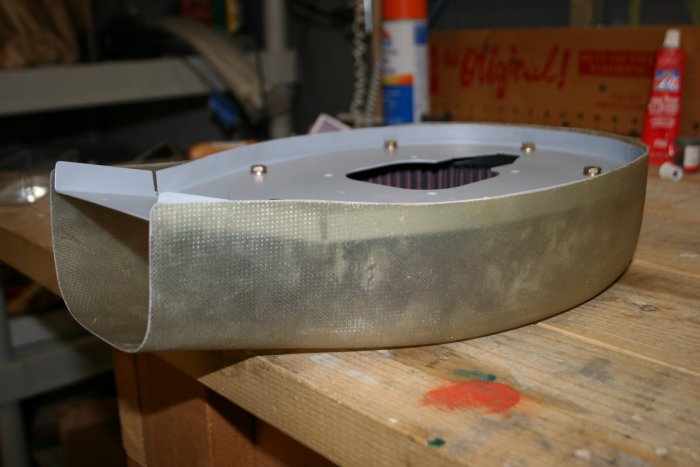

October 4, 2008 - Airbox

The filter goes behind the protrusion

now.

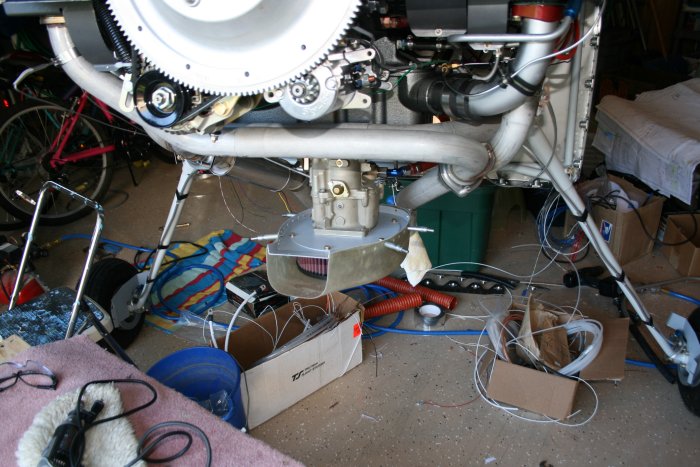

Everything looked OK with the lower

cowl

on.

After having made good progress on the

airbox, I turned my attention to the canopy leading edge. I wiped it

down with my Loehle WonderFil to fill in all the pinholes.

This picture is after the WonderFil application. Those white dots

you see are filled pinholes. I had no idea there were so many.

You can't see them with the naked

eye.