January 5, 2006 - Skin Prep

My son Joe devinyled and deburred the bottom skin and one of the side skins for me Here's the outer side of the bottom skin devinyled and deburred.

Then I took over, smoothing the edges and dimpling the edge holes.

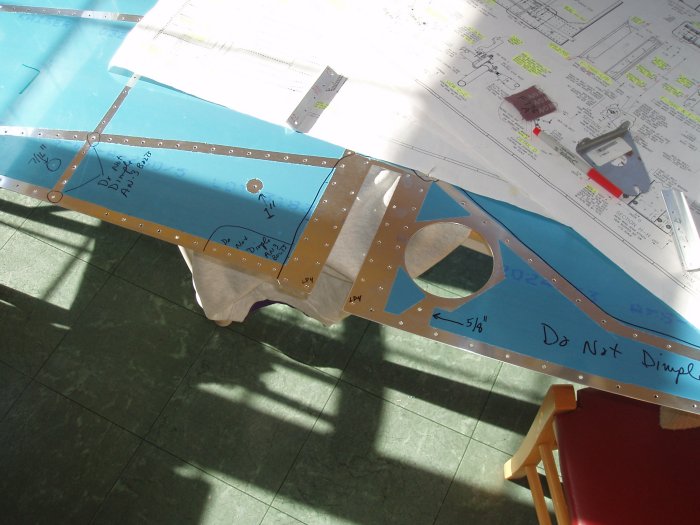

This is one of the side skins. I proceeded with great caution

here, because there are sets of holes that don't get dimpled. Per

the drawings, I marked the skin with a Sharpie all the holes that don't

get dimpled.