January 1, 2007 - Wing Skin Riveting, Trim Servo

I've made the decision not to go the IFR route so eliminates a number of things I would have had to do. Not to mention cost and weight. My engine will be a stock 360, carbureted, so again, nothing out of the ordinary that will require extra effort.

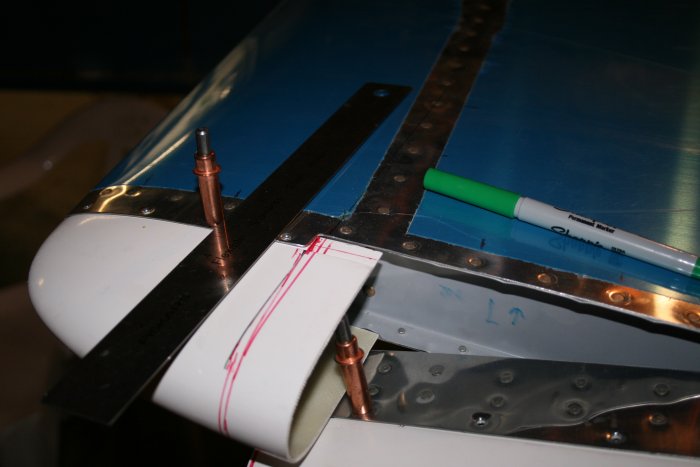

Lynnette and I shot the remaining rivets on the right wing bottom outboard skin. They were fairly easy because I had good access to the rivets through the rib holes on the end rib. The rivets came out well and the right wing is done.

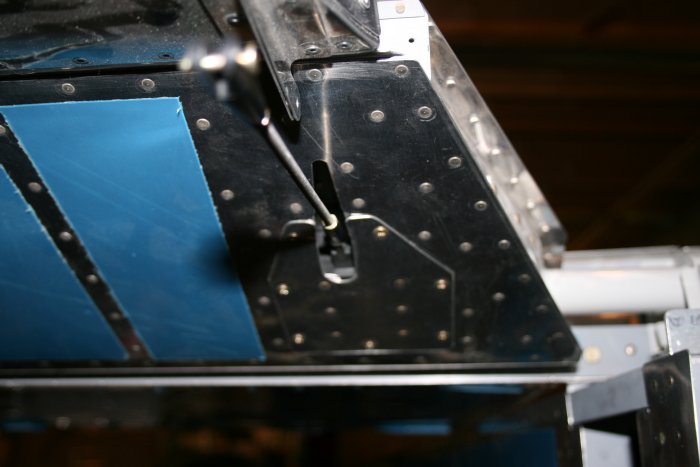

I'll need to trim the threaded push-rod, but I don't want to do that until I run the servo through its full range.

With the trim tab and servo on the elevator, the elevators are fairly well balanced -- just slightly nose heavy. The counterbalance weights are just where they should be at this stage of the project.