March 4, 2007 - Countersinking Mania

|

|

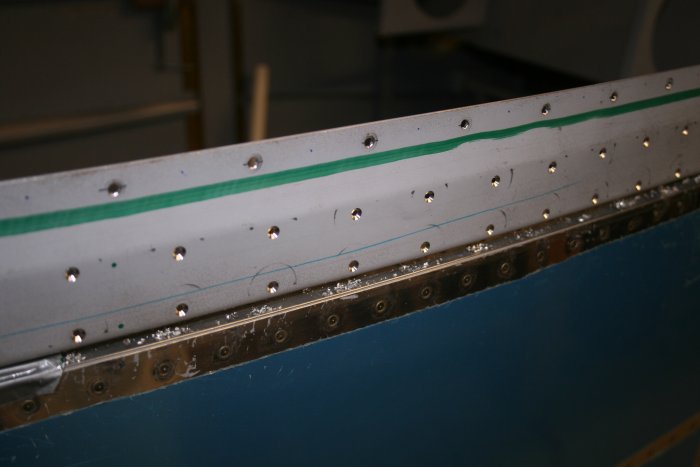

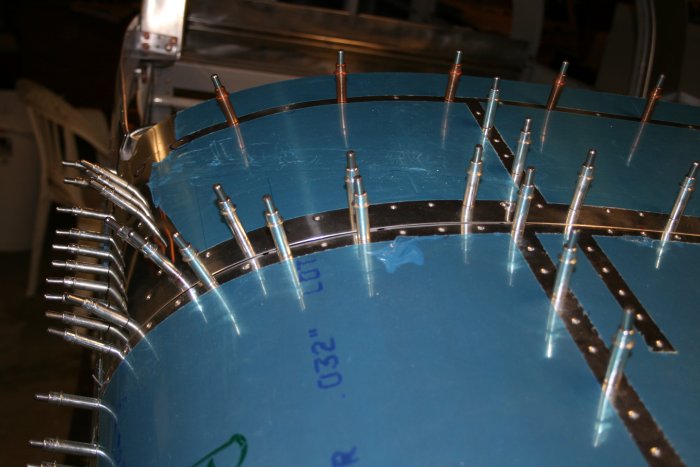

It was too windy to go flying this Sunday, but I had a productive day

prepping the canopy frame and skin for riveting. I wasn't sure if I

should dimple or countersink the side skirts. The canopy frame side

wildments seemed fairly thick so I tried countersinking one hole. It

worked fine. So I countersunk the two lower rows on the side

weldments. |

|

|

|

|

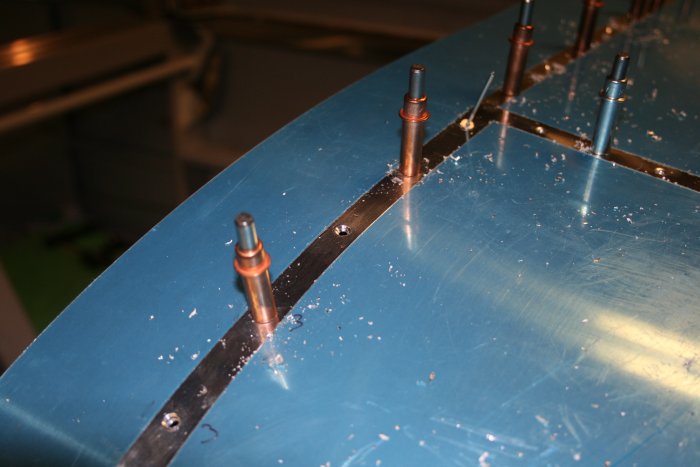

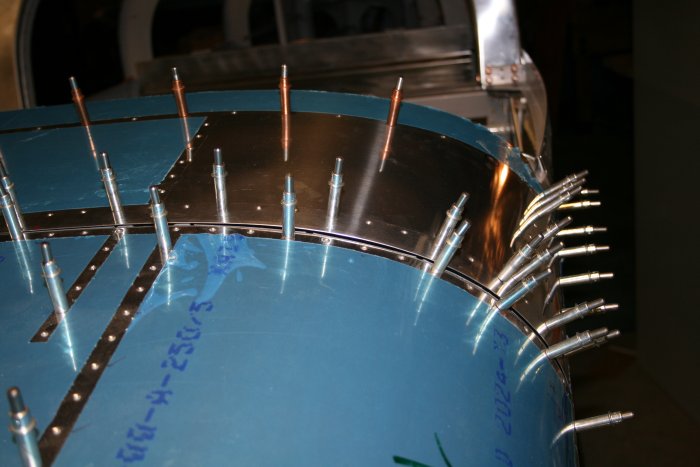

Then I dimpled the side skirts, the lower two rows to #40, and the top

row for a #6 screw.

|

|

|

|

|

You don't believe me? Here's a close-up/ |

|

|

|

|

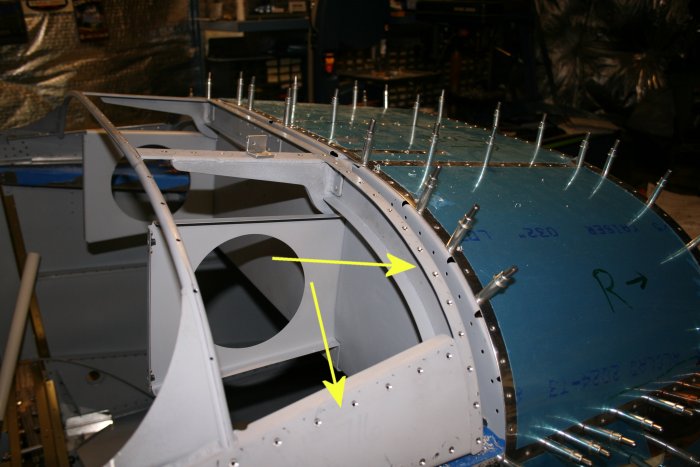

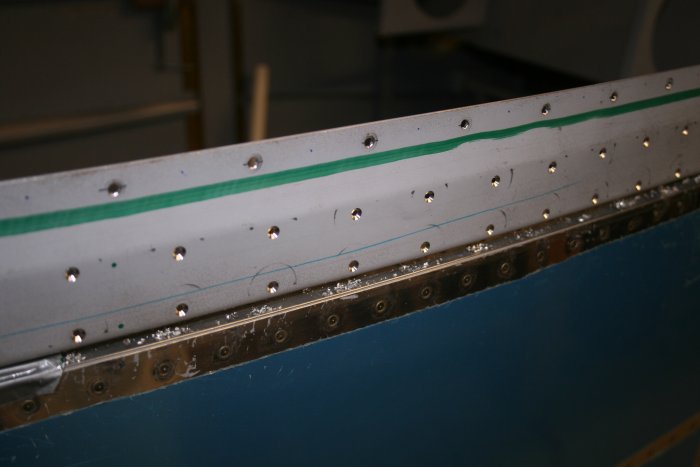

Next I countersunk the canopy frame itself. The canopy frame was

thick enough to countersink, but not thick enough to prevent chattering

by the countersink bit. I solved that by using a little bit of

angle -- seen sitting on the top of a rib -- which I would hold

underneath the hole for backing.

|

|

|

|

| I countersunk the canopy frame

until about 1PM, when I drove out to Essex Skypark to do a little

maintenance on the Citabria. It was cold and windy and the skypark was

deserted. Here the Citabria sits forlornly, wanting to fly. I

recharged the left brake. |

|

|

|

| The skypark wasn't quite deserted.

This is Tiger, the airport cat. |

|

|

|

|

Too windy to fly, too cold to want to. No place to go,

anyways. I need to live in one of those airport

communities in Florida! |

|

|

|

|

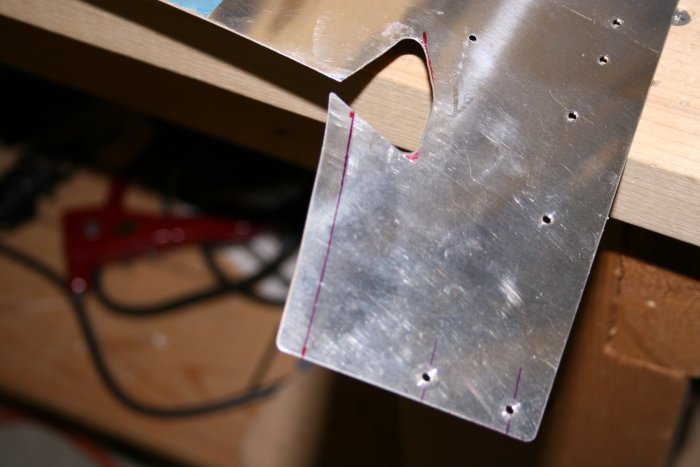

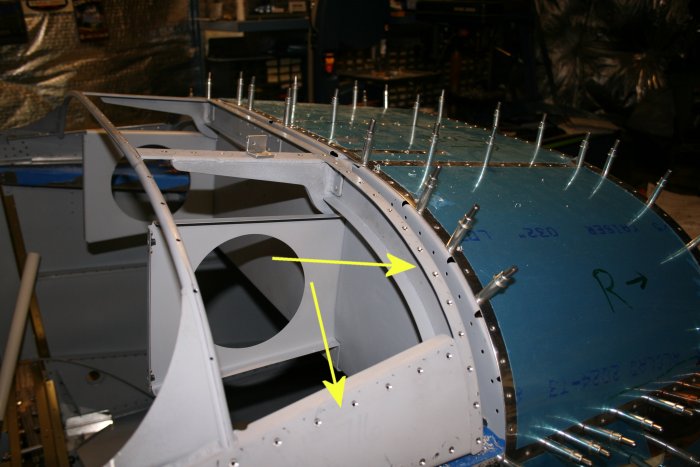

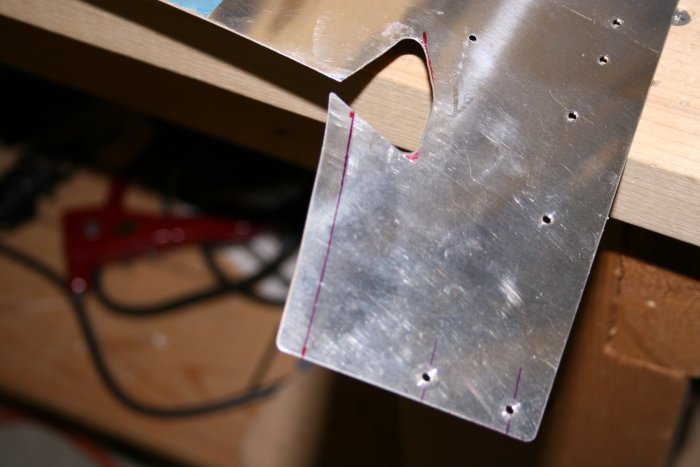

Upon returning home, it was back to work building an airplane. The

canopy skin "ears" need trimming -- indicated by the purple line -- so

they will be aligned horizontally with the side skirts.

|

|

|

|

|

I trimmed the canopy skin ears, deburred all the holes and dimpled the #40

holes. I couldn't reach a few of them with the Main Squeeze, so

Lynnette helped me dimple them with the C-frame. It's been awhile

since I've done this type of work. It was fun. |

|

|

|

|

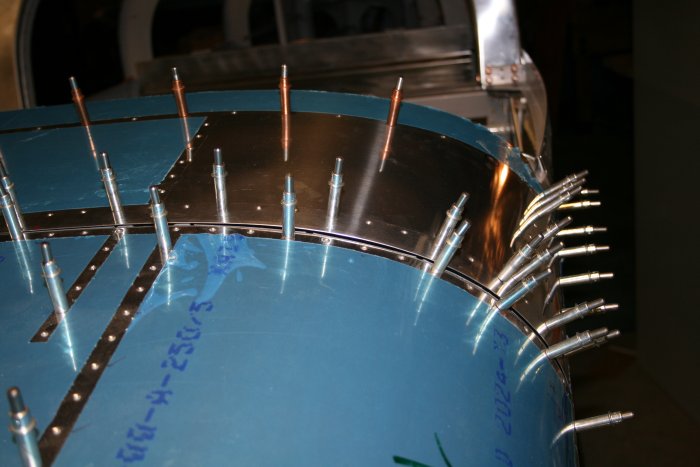

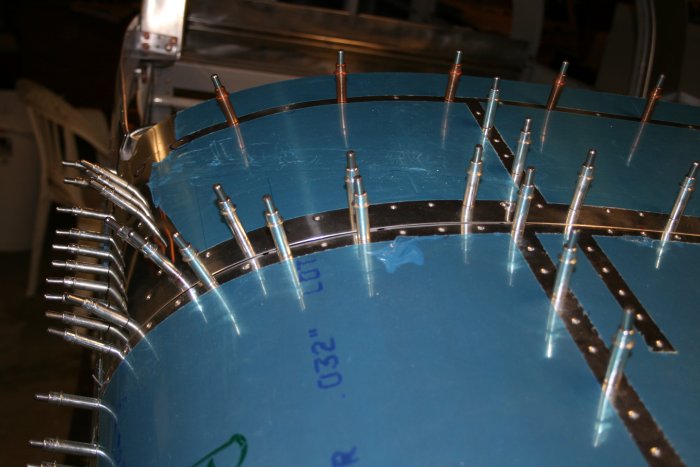

I clecoed the canopy skin back on. Notice the gap between the

canopy skin and the forward skin. This is common, I understand.

What I'll do is put a shim under the forward skin so it is the same

level as the canopy skin.

|

|

|

|

| The right side has a gap too, but

not as bad as the left. |

|

|

|

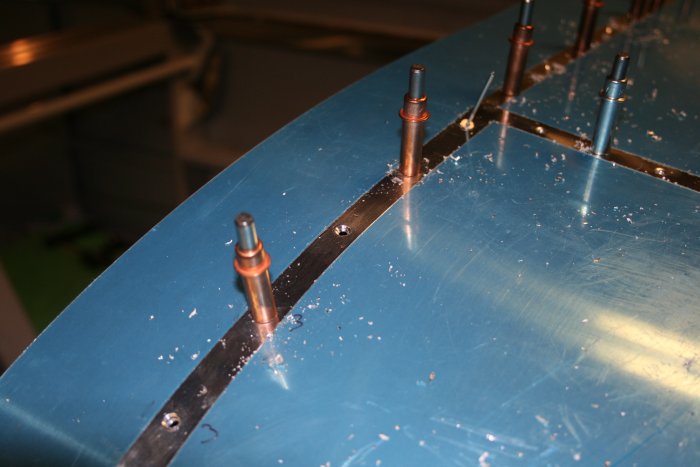

| I had wondered how to handle the

rear row of holes on the canopy skin, which are #30 and are filled with

flush pop-rivets. Dimple or countersink? There is just an

aluminum tube underneath. Dimpling the skin and countersinking the

tube didn't seem like it would work. I did a search on the Vans Air

Force forums and the answer was to countersink the canopy skin and

underlying tube simultaneously. So that's what I did. It should

work fine. |

|

|

|

| |

|

|

|

|

|

|

|