April 12, 2007 - Rear Spar Drilling

Before I could drill the rear spars to the fuse, I had to make sure the

wings were straight with each other and at the proper incidence. I

hung a plumb bob from the inboard and outboard of each wing and made

sure they were aligned along a laser line. I had to push the

outboard edge of each wing aft a little to get the plumb bob all one the

line.

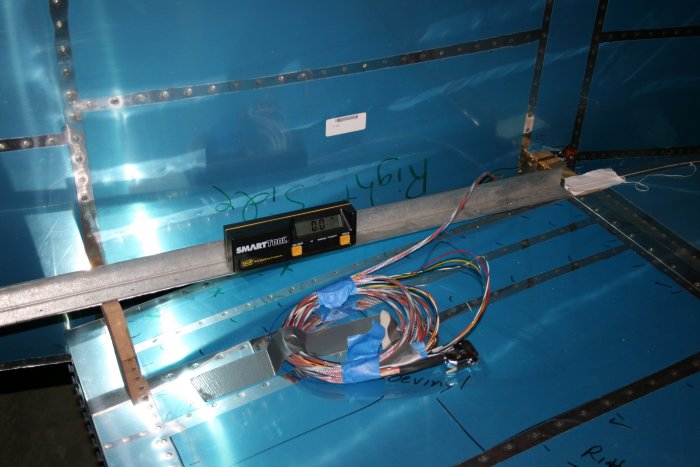

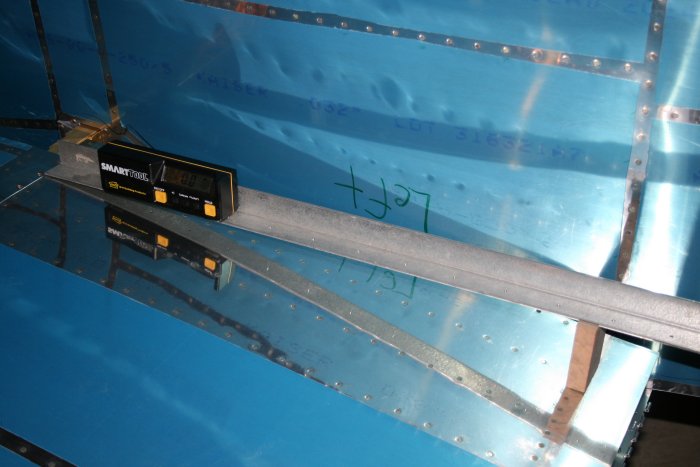

Then I cut a piece of particle board to 3" and used it to support a

steel angle as shown below. The angle is supposed to be absolutely

horizontal and amazingly enough, the SmartTool showed 0.0 degrees!

I did the same thing at the middle and outboard of the wing. I

guess if the wing had any twist, you SmartTool would tell the tale.

But my wings appear straight, as all the readings were either 0.0 or

0.1.

I also measured the height of each wing tip -- they were equidistance.

Finally I measured from each wing tip to a point on the aft fuselage.

Equidistance. Bottom line, the wings are straight and have the

proper incidence. It's time to drill the rear spars.

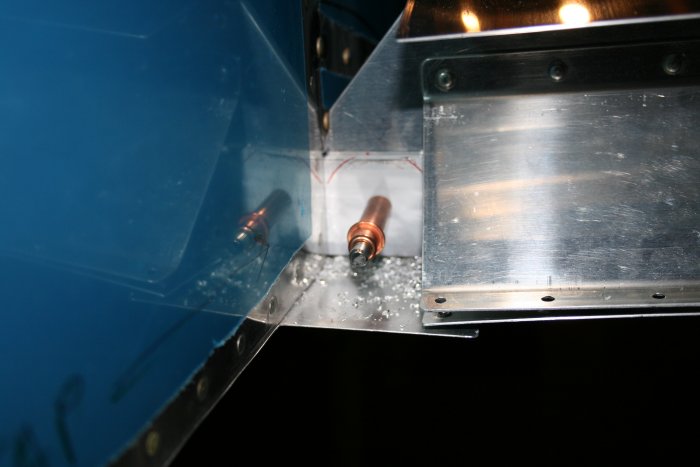

I had bought this drill jig device some time ago. You use it to

keep your drill bit perpendicular to the work.